|

Steel Rolls 'as-cast' without heat treatment are not

suitable for rolling. Dendritic structure, coarse grain, non-homogeneity

and internal stresses make it poor in mechanical properties. So these

rolls are subjected to precisely Comentite/Ferrite more evenly while

retaining the basic Pearlitic structure so important to Alloy Steel

Rolls. Steel Rolls 'as-cast' without heat treatment are not

suitable for rolling. Dendritic structure, coarse grain, non-homogeneity

and internal stresses make it poor in mechanical properties. So these

rolls are subjected to precisely Comentite/Ferrite more evenly while

retaining the basic Pearlitic structure so important to Alloy Steel

Rolls.

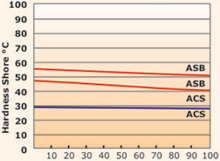

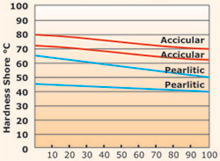

Such rolls have higher strength at cost of hardness decrease compared to

Chill or S G iron Rolls, making them suitable for heavier passes and

severe stress in the roughing & intermediate stands.

Alloy cast Rolls are chiefly applied for the mills where the strength or

biting quality is taken into further consideration than wear resistance.

A wide range of Alloy cast Steel Rolls have been developed to meet

individual applications, depending on their carbon content and heat

treatment.

Alloy steel Base Roll performance in rolling operation is generally

placed in middle way, lying between the quality of Alloy Cast Steel

Rolls and that of S G Iron Rolls.

The rolls are heat treated for many hours under the rigid control of

metallurgical standard. Their resistance to wear and abrasion of the

rolls is quite excellent.

These rolls are incomparable for rolling Rails, Angles, Channels, and

Beams, where deep passes are necessary. They are specially recommended

for high tonnage of Billet, Sheet bar and rails and where very long

rolling period is required. They are extensively used for duty work,

such as blooming and slabbing. |

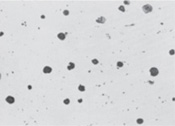

Nodular pearlitic rolls are widely used for hot

rolling applications in different type of Roughing and Intermediate

group stands. The material consists of graphite and carbides in pearlitic matrix.

Nodular pearlitic rolls are widely used for hot

rolling applications in different type of Roughing and Intermediate

group stands. The material consists of graphite and carbides in pearlitic matrix.

Steel Rolls 'as-cast' without heat treatment are not

suitable for rolling. Dendritic structure, coarse grain, non-homogeneity

and internal stresses make it poor in mechanical properties. So these

rolls are subjected to precisely Comentite/Ferrite more evenly while

retaining the basic Pearlitic structure so important to Alloy Steel

Rolls.

Steel Rolls 'as-cast' without heat treatment are not

suitable for rolling. Dendritic structure, coarse grain, non-homogeneity

and internal stresses make it poor in mechanical properties. So these

rolls are subjected to precisely Comentite/Ferrite more evenly while

retaining the basic Pearlitic structure so important to Alloy Steel

Rolls.